Spiral Wound Gasket

Metal spiral wound gasket is made from metal strip spiral winding with non-metallic material filler, and support rings are available inner and outer metal ring - CiXi Feite Sealing Material Co., Ltd.

DESCRIPTION: FEITESEAL G110 Spiral Wound Gasket

Gaskets are formed of V-shaped metallic stripe and soft non-metallic filler by means of piled, spiral wound and connected its end and beginning by dot welded. Depend on its excellent compression resilience it is suitable for sealing spots where the alteration of temperature and pressure are frequent. Spiral Wound Gasket support rings, inside and Outside the spiral winding, improve the Spiral Wound Gasket’s handing,fitting and Versatility. Spiral Wound Gasket can be used as the static sealing element of pipe, valve, pump, thermal exchange, condensing tower, plain hole and man hole of flange, etc. Metal gasket has been widely applied in the fields of petrochemical, mechanical manufactory, power station, metallurgy, shipbuilding, medical and pharmaceutical nuclear power station and navigation, etc.

Products are manufactured in accordance with all relevant Spiral Wound Gasket standards to suit flange designations: ASME B 16.20, ASME B 16.5, BS1560, ASME B 16.47 A (B), BS EN 1092, DIN, JIS, and NF, etc.We can also produce according to clients’ metal gasket request.

Sprial Wound Gasket Types

|

Types

|

Style

|

Flange

|

Example

|

|

Basic type SWG

|

SW110-R

|

Tongue and Groove

|

SS316L/PTFE

|

|

SWG with inner ring

|

SW110-IR

|

Male and Female

|

304 304/FG

|

|

SWG with outer ring

|

SW110-CG

|

Raised face

Flat face

|

304/ASB CS

|

|

SWG with inner

& outer rings

|

SW110-CGI

|

316L 316L/FG CS

|

|

|

SWG for heat exchanger

|

SW110-H

|

Heat exchanger

|

304/FG with 1 bar of DJ

|

|

Special shape SWG

|

SW110-S

|

Special

|

Oval

|

|

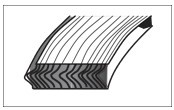

SW110-R Basic Type Basic construction type, inner and outer diameters are reinforced with several piles of metal without filler to give greater stability and better compression characteristics. – Suitable for tongue and groove, male and female or grooved to flat face flange assemblies. |

|

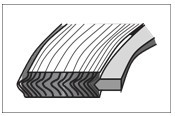

SW110-IR Inner Ring Type Solid inner metal ring acts as a compression stopper. To prevent accumulation of solids, reduce turbulent flow of process fluids and minimize erosion, damages of gasket between flange bore and the inside diameter, the annular space is filled up by solid inner metal ring. – Suitable for male and female pipe flanges. |

|

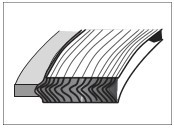

SW110-CG Outer Ring Type Solid outer ring accurately locates the gasket on the flange face to give the additional radial strength to prevent the gasket blowout and acts as a compression limiter. In case of installing the outer ring, it is very easy to install the gasket to flange face because the end of outer ring will touch at bolts – Suitable for use with flat face and raised face flanges. For class 900 and above an internal ring is recommended. |

|

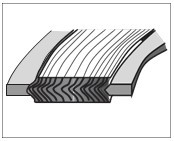

SW110-CGI Inner & Outer Rings Type A inner ring and outer ring type gasket will give an additional compression limiting stopper for gasket inner and outer side. It will prevent the corrosion on flange face at annular space. – Suitable for use with flat face and raised face flanges and specified for high pressure / temperature service – Class 900 and above or where corrosive or toxic media are present. |

Metal Gasket Material Selections:

>SWG Inner and Outer Ring Material: Carbon Steel, 304(L), 316(L), 321, 317, 31803, Monel, Ti, Ni, INC825, INC625, Hast.C/B etc.

>SWG Hoop/Winding Material: 304(L), 316(L), 321, 317, 31803, Monel, Ti, Ni, INC825, INC625, Hast etc.

>SWG Filler material: Graphite, PTFE, Asbestos, Non-asb, Mica etc

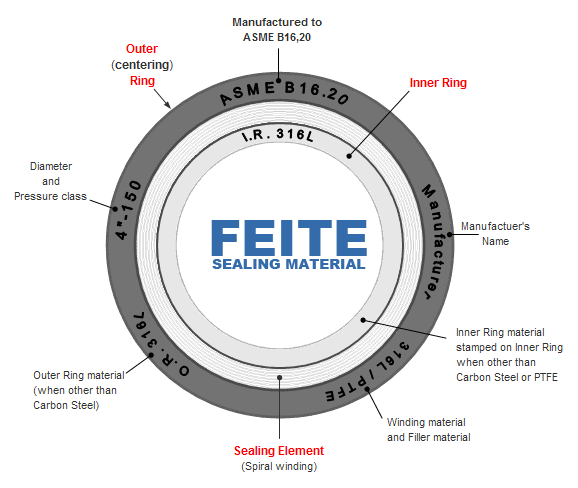

Spiral Wound Gasket Stamp Marking Example:

Order Example:

Spiral wound gasket,Type CGI, Material 316L/316L/FG/CS, Size 2″ 150# ASME B16.20, Qty 1000pcs